The story of Dundee’s jute industry

In the mid-19th century, Dundee’s fortunes revolved around jute. The first bales of jute fibre arrived by ship from Bengal in 1820, and by the 1890s, more than 120 jute mills were in operation, employing around 50,000 people. The majority of jute workers were women and children because they cost less, and serious accidents were common. By 1914, the industry was in decline. The last ship to bring bales of raw jute from India was the ‘Banglar Urmi’ in 1998, and Dundee’s last jute mill, Taybank Works, closed in 1999.

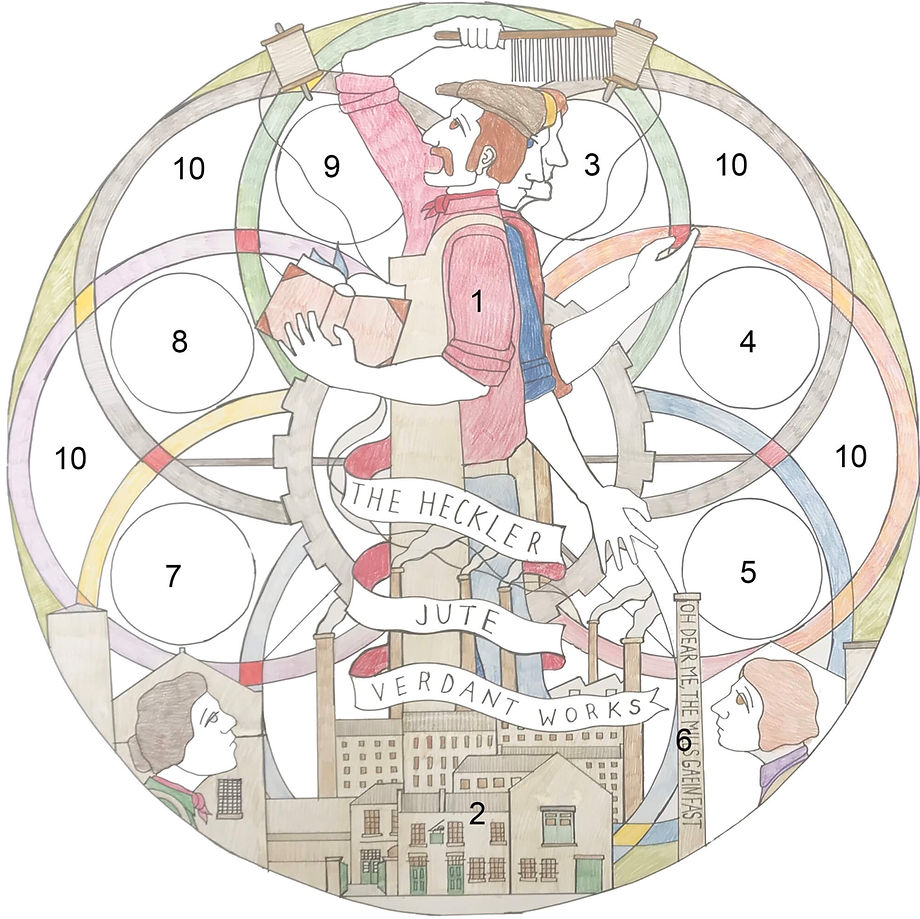

1. Jute workers

Working in a jute mill was exhausting, poorly paid and very dangerous – many workers lost their hearing from the noise of the machinery or developed breathing difficulties. From 1876 onwards, children under 13 combined mill-work with school and became known as ‘half-timers’ – either attending school every other day, or in the afternoons. Some mills even had their own schools.

2. Verdant Works

Verdant Works is one of Dundee’s best-known mills and it was built in 1833 for flax merchant David Lindsay. In the mid-1800s, the mill switched from flax to jute, but all production ceased by the late 19th century. Verdant Works opened to the public as a museum in 1996, and is now owned by Dundee Heritage Trust. As a rare surviving example of a courtyard-type mill, it carries a Category ‘A’ listing.

3. Jute production

Dundee’s jute mills used water from Scouring Burn, Dens Burn and Dighty Burn to power the steam engines, and to process the jute.

4. ‘Heckling’ the jute

The ‘heckling’ process involved splitting and straightening the jute fibres, before they were spun into coarse yarn for weaving.

5. Jute bales

These came from Bengal, an area now divided between India and Bangladesh. Each jute bale weighed almost 200kg, and was known as a ‘pukka bale’.

6. ‘Oh dear me, the mill’s gaein fast’

A lyric from a song called ‘Oh Dear Me/Jute Mill Song’ by socialist songwriter Mary Brooksbank.

7. Jute plant

The jute plant (Corchorus olitorius) takes around three months to grow from seed to harvest.

8. Reels of jute

During the spinning process, jute fibres were twisted together to create a continuous thread and the resulting yarn was wound onto bobbins or reels.

9. Rope-making

Jute is fully biodegradable and recyclable, and is still widely used today in carpet-making, agriculture and packaging. In the 19th and early 20th centuries, the long jute fibres were also used for rope-making at Tay Rope Works in Dundee’s West End.

10. Dundee mill names

Today, former jute mills in Dundee have new identities: Verdant Works is a popular museum, Baxter Brothers Works has become Hotel Indigo, and other mills have been turned into apartments and workshops.